PASCHAL for the 7th time at the Saudi Build international trade exhibition

At the Saudi Build exhibition in Riyadh from the 17th to the 20th of October 2016, PASCHAL will present wall, column and shaft formwork as well as the H20 beam in combination with the TG 60 shoring system for high, horizontal concrete structures.Given its long-standing presence in the Arabian construction market, PASCHAL is concentrating its exhibits on the primary applications in the Arabian world.

In hall 3, booth 217-3 PASCHAL will demonstrate the practical application options, the system diversity and the compatibility of the systems and components for quick and easy use in reinforced concrete construction on a 50 m² booth. Upon request extremely well-trained formwork experts with a great deal of practical experience will show visitors to the booth the simple handling and also some of the numerous constructions and projects completed.

The following will be presented and demonstrated at Saudi Build in Riyadh:

Modular formwork

Two PASCHAL systems on a current building site in Riyadh. In the foreground, the Modular panels stand upright as wall formwork.

Two PASCHAL systems on a current building site in Riyadh. In the foreground, the Modular panels stand upright as wall formwork.

In the background, the slab formwork is being prepared with the yellow H20 beams.

The Modular universal formwork is preferred for use in formwork for foundations, walls, columns, beams, shafts and pre-cast concrete components. As a result of the comprehensive range of elements, it can be used both as hand-set and large-size formwork. The modular design principle enables simple and quick handling, even by unskilled labour.

Modular column formwork

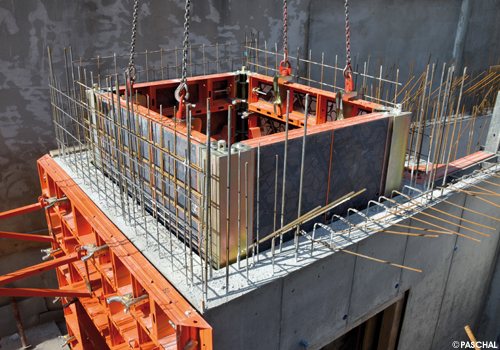

The adjustable Modular column formwork in practical use.

The adjustable Modular column formwork in practical use.

As a practical system expansion of the Modular formwork system, at Saudi Build PASCHAL will be exhibiting the adjustable Modular column formwork with which both square and rectangular reinforced concrete columns with external dimensions from 20 to 50 cm in increments of 5 centimetres can be formed. The simple windmill principle allows you to form a wide variety of different reinforced concrete columns from just a few individual panels of the adjustable Modular column formwork. Depending on availability and space constraints, the formwork systems can be moved completely by using a crane or can be dismantled into individual components and transported, assembled and dismantled manually.

Dismantling inside corner post

The adjustable dismantling inside corner post simplifies and reduces the time needed to build, to dismantle and to relocate the inside formwork of steel reinforced concrete shafts.

The adjustable dismantling inside corner post simplifies and reduces the time needed to build, to dismantle and to relocate the inside formwork of steel reinforced concrete shafts.

Frequently, massive steel reinforced concrete shafts that fulfil a double function in the form of lift shafts or supply shafts are necessary for the stiffening of reinforced concrete skeletons. For quick and precise execution PASCHAL offers the dismantling inside corner post to the Modular formwork system. Each dismantling inside corner post has a hexagon nut on top of the inside corner post in order to open or close the corner posts.

A size 36 spanner can be used for this or a DW 15 tie rod which fits in the hexagon nut would also work.

The benefits of PASCHAL's dismantling inside corner post can be seen in particular when dismantling the formwork. They can be adjusted by approx. 50 mm on each side. When opening the corner posts, the entire formwork frame can be loosened and lifted within one move. The disassembly of the inner formwork is completely superfluous.

LOGO.3

To create formwork for large surfaces, LOGO.3 elements can be put together using wedge clamps to make large-size units.

To create formwork for large surfaces, LOGO.3 elements can be put together using wedge clamps to make large-size units.

The LOGO.3 wall formwork system will be displayed in its steel and aluminium versions. The robust formwork elements with profiled flat frames stand for robustness and durability. The elements can be used both horizontally and vertically. Connection of the elements is performed by using a light wedge clamp that weighs only 1.8 kg, or by using a multi clamp. The comprehensive range of elements also includes multi elements for corners, columns and stop ends. Moreover, the LOGO.3 formwork system is a winner when it comes to large-scale concrete constructions with minimum tie points of just 0.62 tie points/m².

TTR

There is no alternative to the Trapezoidal girder formwork if precisely rounded concrete constructions are planned. Pre-assembled and pre-curved formwork units fit exactly and are a guarantee for perfect curvatures.

There is no alternative to the Trapezoidal girder formwork if precisely rounded concrete constructions are planned. Pre-assembled and pre-curved formwork units fit exactly and are a guarantee for perfect curvatures.

The TTR Trapezoidal girder formwork, with its continuously adjustable diameter from 2 to 5 metres and from 5 metres to infinite, provides well-formed concrete curvatures that correspond exactly to the specifications and drawings when executed.

System enhancements enable usage on and to sloping surfaces, and compatibility with all additional PASCHAL formwork systems enables creative and unique concrete forms to be implemented for aesthetic reasons and/or due to design requirements.

Pre-assembly carried out in the factory and the low proportion of tie points of just 0.28 to 0.55 tie points/m2 enable shortest possible forming times.

H20 beam combined with the TG60 shoring system

When combined, the TG 60 shoring system and the H20 beam are unbeatable in terms of loading capacity and flexibility.

When combined, the TG 60 shoring system and the H20 beam are unbeatable in terms of loading capacity and flexibility.

The TG 60 shoring system is ideal for constructing heavy-duty supports, shoring towers, stair towers and support scaffolds with great load-bearing properties. The TG 60 shoring towers can be assembled both standing up or in horizontal position. In order to transmit possible tensile forces, the individual frames are secured with hinged pins or bolts. As such, the system can be assembled on the ground and then subsequently lifted into position using a crane.

At Saudi Build, we will show how easily and flexibly the TG 60 shoring system can be combined with H20 beams, for example to safely ensure the load transfer of slab formwork.

The adaptability of the H20 beam is achieved by simple overlapping. Therefore, it is not important if the beam is functioning as main beam or cross beam. The H20 beam comes in lengths of 245 cm to 600 cm. The permitted shear force of the 20 cm high wooden beam is defined as Q=11.0 kN and the permitted bending moment as M=5.0 kNm.

Alternatively, the 22.5 cm high aluminium beam from the GASS programme can be used as main beam and as cross beam. The aluminium beams are available in lengths from 1.80 m to 7.20 m.