LOGO.3 in the precast reinforced concrete plant of Beton Tille GmbH & Co. KG

Regulated water flow with frame outlets made of precast reinforced concrete elements under rail tracks and a federal highway.The continuation of the new route requires the relocation of existing traffic routes

Further on in the course of the construction of the new B 252, in the Sarnau section, the Lahn cycle path, Federal Highway 62 and the railway line have to be relocated to make room for the new bypass. The RB 42 railway line between Marburg and Frankenberg was laid between Sarnau and Niederwetter over a length of around 600 meters and runs at around 30 meters' distance from its previous route.

Another frame element is ready for transport to the construction site, precisely dimensioned and with perfect concrete surfaces

This also required adjustments to the RB 94 railway line between the Sarnau train station and Sarnau.

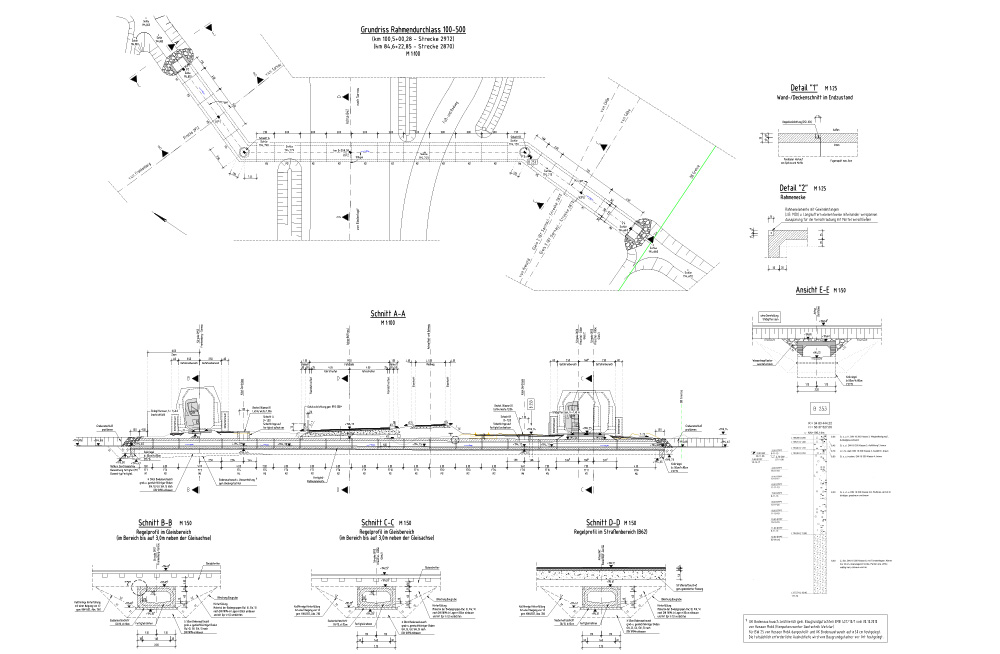

For safe and targeted surface drainage, a frame passage made of precast reinforced concrete elements was laid under the railway lines from Biedenkopf to Sarnau, from Kreuztal to Colbe, the footpath and bike path and under the B 62 over a length of 62 m.

A built-in center piece. The support of Beton Tille GmbH & Co. KG and their high-quality manufacturing significantly reduced the specified soil cover over the precast concrete parts.

A built-in center piece. The support of Beton Tille GmbH & Co. KG and their high-quality manufacturing significantly reduced the specified soil cover over the precast concrete parts.

Frame passage made of precast concrete parts

The production and delivery order for the construction project was placed with Beton Tille GmbH & Co. KG.

For this construction project as well, Managing Director Friedrich-Wilhelm Reineke also worked out a pragmatic solution proposal together with those involved in the construction, and rented formwork material from PASCHAL to implement the project.

The LOGO.3 wall formwork system in the precast reinforced concrete plant

Using 40 m² LOGO.3 wall formwork, with element dimensions 135 x 270 cm, 17 precast reinforced concrete elements were produced in the Beton Tille GmbH & Co. KG factory.

The longest frame passage element measures 7.00 m. In addition to the straight precast reinforced concrete elements, two 45° angle elements with an inspection entrance and two end elements with an incline for installation in the embankments were also manufactured.

Beton Tille GmbH & Co.KG used self-manufactured steel cores to produce the inner profiling. The external formwork consisting of LOGO.3 elements was precisely fixed using inclined supports and the C35/45-quality concrete that was poured in was compacted using internal vibrators. The front parts of the precast concrete elements were manufactured using the "tongue and groove principle" and to the specified tolerances. They serve to securely connect the elements among themselves.

Before installation, i.e., the process of pushing one element onto another, a self-adhesive squeeze joint tape was applied to the reveal.

The wall formwork system LOGO.3 used at Beton Tille GmbH & Co. KG for forming frame passage elements.

Whether for series or individual production – the systems from PASCHAL will fit your needs

“This application highlights the universal applicability of PASCHAL formwork systems. To supplement our factory formwork, the required formwork material was accessed from the PASCHAL rental park on short notice,” says Managing Director Friedrich-Wilhelm Reineke.

Beton Tille GmbH & Co. KG is an established precast concrete factory which has proven its efficiency and manufacturing quality across numerous projects. The precast concrete plant repeatedly uses rented equipment from PASCHAL for unusual and special solutions.

The frame passage in its entirety highlights the dimensions of this construction phase with the coordinates 50.87286984204861, 8.763770114445407 for laying the B 252.

« Current News