Buried treasures

Security of supply after the phasing out of nuclear energy

1,100 concrete foundations for natural gas storage stations in EtzelGermany’s own sources of crude oil and natural gas is only enough to supply a small section of the country; Germany is thus dependant on deliveries from abroad. In 1970 it was decided to compile a strategic “state crude oil reserve” for the demand of approximately 65 days.

The oil crises of 1973 and 1979 confirm that this was the correct decision. Nowadays, there is also a lot natural gas in addition to the oil.

How and where is this amount stored?

Siting

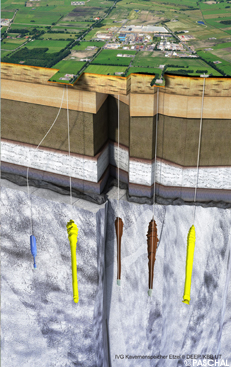

Artificial caverns in deep salt domes in northern Germany prove to be the best solution for storage. All requirements and safety aspects were fulfilled here.

All of the salt domes are in Etzel. These are very well suited for federal German reserves due to their structure, expansiveness and geographical location. It is approximately 12km long, 4km wide, rooted 4km deep and the dome is covered by young layers of earth that are 750m thick.

Etzel (Friedeburg community, district of Wittmund, East Frisia, Lower Saxony)

Etzel is a small town in the Freideburg community in East Frisia. Wilhelmshaven is 10 km away as the crow flies.

To make caverns in the salt domes, one must dig through the covering layers of earth, deep into the rock-like body of salt. The caverns typically have a diameter of a few tens of metres and the shape of large tubes more than 100m high. The salt masses are dissolved using seawater brought in by a pipeline from Etzel. The salty water rinsed out is transported to the North Sea via a second pipeline and discharged there with official approval.

In recent times caverns have mainly been built for natural gas. The capacity is set to be increased by billions of standard cubic metres over the next few years. The caverns are connected to the European gas network and serve as a storage area of natural gas, above all, for northern Germany.

The seemingly confusing amount of nearly 1,100 strip, raft and block foundations were constructed at Etzel alone at this stage of construction. LOGO.3 provided the most economic solution. The higher elements were installed horizontally, the lower ones vertically; the element connections fit together.

Whilst in the foreground some foundations are already complete, behind it the formwork is repositioned. The larger elements are positioned using the mobile crane, the smaller by hand. The sand means that after the buildings are completed the foundations will not be seen.

Storage technology

At the moment there are three construction areas at the Etzel site. The operational plants (gas purifier, dehumidifier, compressors, etc.) on the earth surfaces located in the structure are essential for storing natural gas in the caverns and later withdrawing it.

E.ON Gas Storage GmbH (Essen), together with OMV Fas & Power GmbH (Vienna), Verbundnetz Fas Aktiengesellschaft (Leipzig) and Gas-Union (Frankfurt), is constructing the ESE – Etzel natural gas storage facility (in German, Erdgasspeicher Etzel). The storage station will commence operation from 2012 to 2012 in stages with a total of 19 caverns and will technically operate by E.ON Gas Storage.

One cavern has a cavity volume of around 700,000m3 and contains approx. 98 million Nm3 of working gas (= gas that is not required for maintaining the minimum pressure and can be used) at 70 to 200 bar. The project has a quantity of orders of around 356 million Euro (status 2011).

Building site organisation

Knoll GmbH (Haren) was commissioned to carry out the carcassing works of lots 1 and 8. The building site comprised of 12 hectares with an additional 1.5ha of stockyards for building site facilities. The carcassing works began in June 2011 and were completed at the beginning of 2012.

The predominant part of the surface was lined with the LOGO.3 by PASCHAL. Only very special areas were subject to another formwork, Modular universal formwork. This is designed for complicated or small-scale formwork problems.

Concrete works: 1,100 different foundations!

Almost 1,100 foundations were built for the buildings but also for the individual pipelines. 700m3 C12/15 concrete were used for the granular subbases, for the construction approx. 3,800m3 C 35/45 (if required XC4, XD3, XF2, XA3-WA), as well as 500 t BST 500 construction steel, woven on site.

Monitoring class II applies on the construction site.

The construction works also are partly running over harsh winter, as some foundations are produced in heatable, 30x40m winter construction tents and positioned on site using mobile cranes.

To increase the corrosion protection of the buried gas high-pressure pipelines, all pipeline foundations were equipped with a “Pohl cover”, in this case made of an undercoat, as well as a bitumen thick coating. The pipeline trenches lie partly 5.0m under ground level.

For the approximate 20,000m² surface to receive formwork, only 300m² of the LOGO.3 system formwork by PASCHAL was used. On average each formwork was in use 66 times. The LOGO.3 was chosen due to its various individual usage options, as well as the possibility of completely lifting the formwork so that it can be reused at the next site without having to reassemble it. The builders value it as durable and flexible system, in which no special solutions were required, especially as the LOGO.3 can be adjusted in the system to 1.0 centimetre at every measurement. At some small, particularly fiddly places the Modular universal formwork, compatible with LOGO.3, was used because of its range of small-area formwork elements in various heights and widths.

Every formwork element was used on this construction site around 66 times. A thorough cleaning of, above all, the plywood, as well as spraying it with formwork oil are important requirements for a smooth, invulnerable concrete surface. All foundations were equipped with a black protective coat, the “Pohl cover“. The smallest foundations measure 25x25cm, the largest many metres.

Adjacent to cast-in-place concrete and precast concrete elements: whilst in the background the workshops are constructed using prefabricated materials (pillar and wall parts can be seen), in the foreground the foundations are produced using cast-in-place concrete. Many elements of the LOGO.3 wall formwork can be carried by 2 men. During winter some foundations were also produced as prefabricated parts, namely in weather-proof tents, however out of cast-in-place concrete.

Foundations for three adjacent pipelines. Construction manager Schütte: “As some pipeline foundations were assembled in winter, foundation quivers had to be concreted with grout after the alignment of the shear cleats and installation parts. For this the foundation had to be encased and heated in order for the cement to set and avoid frost damage. “

Overview of a section of the construction site. This lot alone covers more than 12 hectares, making it the largest construction site in Germany. © KNOLL